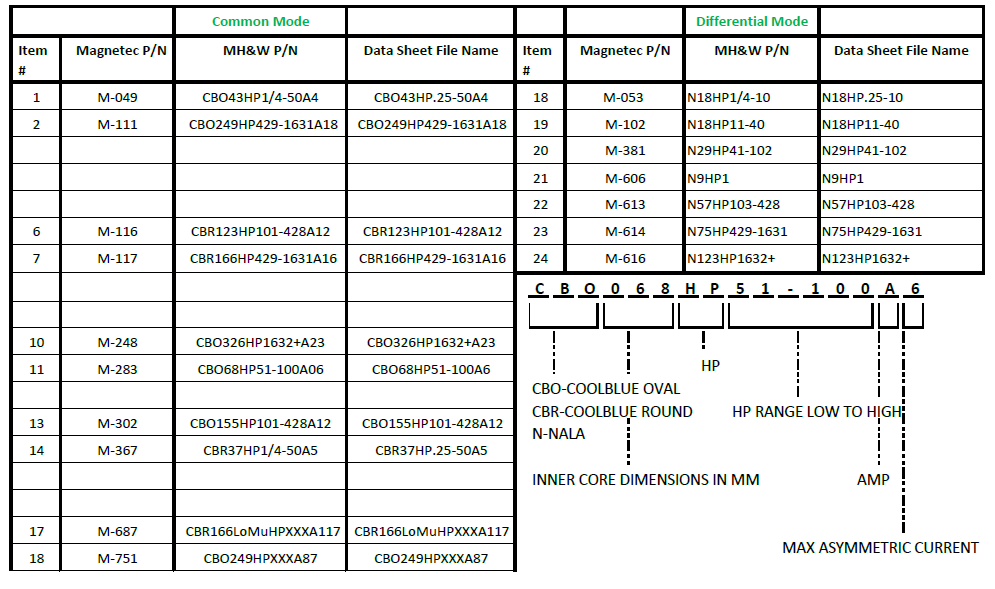

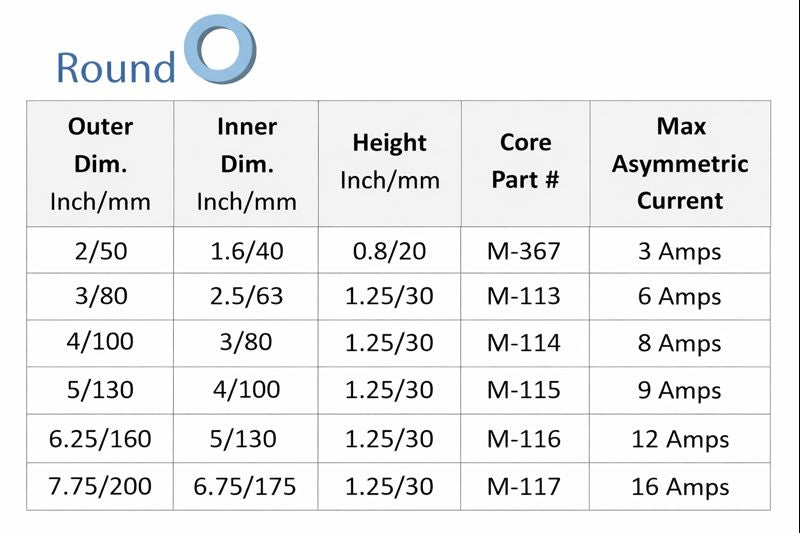

M102, NaLA coolBLUE Differential mode line absorber , VFD 11-40Hp, 30x20x10MM

M102, NaLA coolBLUE Differential mode line absorber , VFD 11-40Hp, 30x20x10MM is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Estimate shipping

Please correct the following errors:

Description

Description

M102, NaLA coolBLUE Differential mode line absorber , VFD 11-40Hp, 30x20x10MM

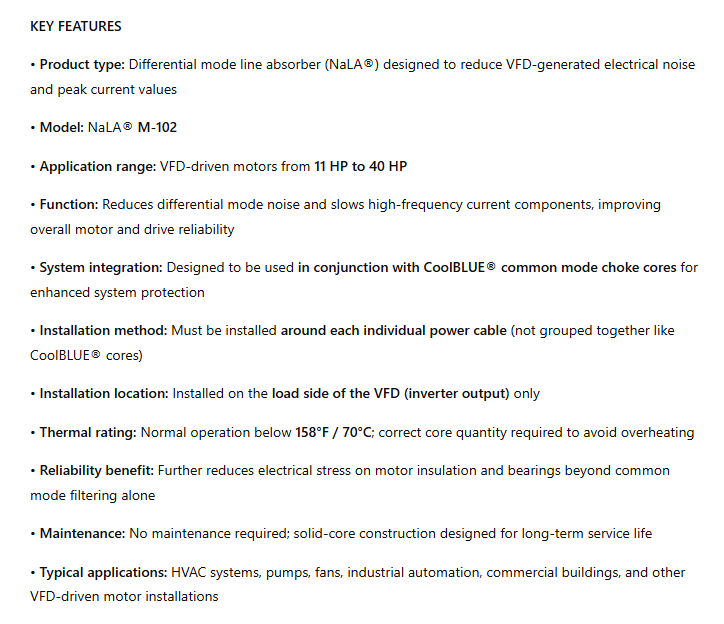

KEY FEATURES

• Product type: Differential mode line absorber (NaLA®) designed to reduce VFD-generated electrical noise and peak current values

• Model: NaLA® M-102

• Application range: VFD-driven motors from 11 HP to 40 HP

• Function: Reduces differential mode noise and slows high-frequency current components, improving overall motor and drive reliability

• System integration: Designed to be used in conjunction with CoolBLUE® common mode choke cores for enhanced system protection

• Installation method: Must be installed around each individual power cable (not grouped together like CoolBLUE® cores)

• Installation location: Installed on the load side of the VFD (inverter output) only

• Thermal rating: Normal operation below 158°F / 70°C; correct core quantity required to avoid overheating

• Reliability benefit: Further reduces electrical stress on motor insulation and bearings beyond common mode filtering alone

• Maintenance: No maintenance required; solid-core construction designed for long-term service life

• Typical applications: HVAC systems, pumps, fans, industrial automation, commercial buildings, and other VFD-driven motor installations

QUANTITY GUIDELINE – NaLA® M-102

• Applicable motor range: 11 HP to 40 HP

• Cable length: up to 150 ft / 50 m

– 1 core per power cable

• Cable length: up to 300 ft / 100 m

– 2 cores per power cable

• Cable length: up to 450 ft / 150 m

– 3 cores per power cable

• Cable length: up to 900 ft / 300 m

– 4 cores per power cable

• Installation rule:

– NaLA® cores must be installed around each individual power cable

– Do not group multiple conductors through a single core

• System integration note:

– Designed to be used in conjunction with CoolBLUE® common mode choke cores

• Thermal consideration:

– Normal operation below 158°F / 70°C

– Using the correct quantity is critical to avoid overheating

CoolBLUE® toroids made from the nanocrystalline material NANOPERM® are

being used increasingly to reduce damaging motor bearing currents in modern

high power inverter systems operating at high switching frequencies. As a result of

these unwanted currents, the bearings corrugate, leading to electrical breakdown

in the lubrication and finally to a standstill of the entire motor.

The use of CoolBLUE® cores not only significantly reduces the over voltage peaks

at the motor terminals, but also suppresses the asymmetrical EMI currents which

are generated by the parasitic capacities of the motor itself together with the motor

cable. In order to achieve an efficient reduction in these destructive effects, one or

more CoolBLUE® cores of suitable geometry have to be placed together over the

connector cables in the DC-link as well as at the inverter output. In this configura-

tion, the cores operate as a common-mode choke.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.