KB ELECTRONIC

KBPC-240D, KB Electronics, 9338, DC Drive,1/50 TO 2HP,115/230V, NEMA 4X,

Regular price From $499.95Unit price /UnavailableIn stock (40 units)KB ELECTRONIC

KBMD-240D, KB Electronics DC Drives, KBMD Series, 9370 SCR, 1/100-2HP CONTROL, 115/230VAC, 1-WAY

Regular price From $362.46Unit price /UnavailableIn stock (29 units)LENZE

ESV222N02YXB, VFD, SMV, Drive 3 Hp, 240 Volts, 1/3Ph, Nema1, 9.6Amps,

Regular price $799.95Unit price /UnavailableIn stock (12 units)LENZE

ESV152N02YXB, VFD, SMV, Drive 2 Hp, 240 Volts, 3Ph, Nema1, 7 Amps,

Regular price $598.18Unit price /UnavailableIn stock (10 units)DART CONTROL

Regular price $248.73Unit price /UnavailableIn stock (6 units)WEG

Regular price $152.20Unit price /UnavailableIn stock (4 units)KB ELECTRONIC

Regular price $493.74Unit price /UnavailableBackorderedTECO WESTINGHOUSE

L510-201-H1-U, Westinghouse, Drives, VFD, 1 Hp, 230V IN, 230V output, Ip20

Regular price $428.31Unit price /UnavailableIn stock (6 units)KB ELECTRONIC

KBWA-23D, KB, 9946, 1/2 hp, 115/230V, Nema1,2.4A, 208/230V, 1Ph input

Regular price $399.55Unit price /UnavailableLow stock (3 units)KB ELECTRONIC

KBMG-212D, KB, Drive, DC, 120/240VAC, 1.2A, Chassis Thru 1/6HP, SCR, 90/180VDC Armature, Regen

Regular price $375.77Unit price /UnavailableVery low stock (2 units)WEG

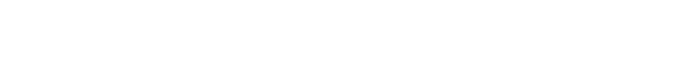

PESW-B9D45EX-R61, Enclosed Starter, 5Hp@575, 600 V Coil with Stop-Reset Pushbuttons - Three Phase

Regular price $156.81Unit price /UnavailableIn stock (7 units)WEG

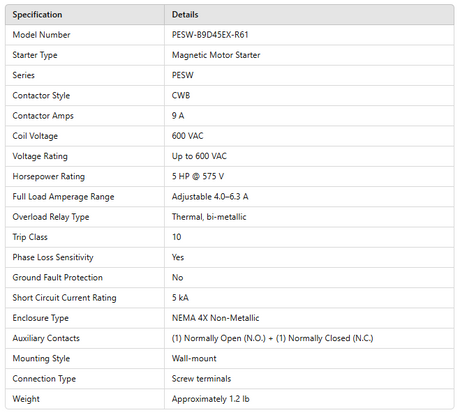

Regular price $152.20Unit price /UnavailableIn stock (7 units)WEG

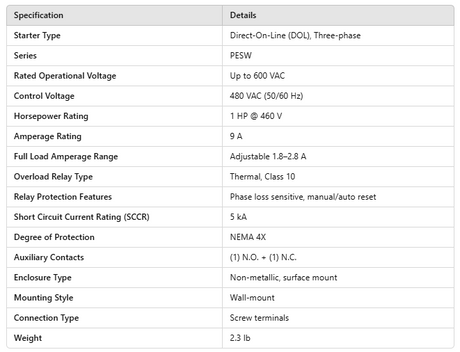

PESWS-25V24AX-RM33, Weg, 5HP, 1PH, 25 Amps, 230V, Nema 4X, MotorStarter

Regular price $224.47Unit price /UnavailableIn stock (6 units)LENZE

ESV752N02TXB, VFD, SMV, Drive 10 Hp, 240 Volts,3Ph, Nema1,174617.00,

Regular price $1,248.98Unit price /UnavailableIn stock (8 units)TECO WESTINGHOUSE

L510-202-H3-U, Teco, 2 Hp, 230 Volts, 3 Phases, Chassis IP20,7.5Amps,

Regular price $440.55Unit price /UnavailableVery low stock (2 units)LENZE

Regular price $1,268.85Unit price /UnavailableIn stock (4 units)KB ELECTRONIC

9443, KBIC SI-5 Signal Isolator

Regular price $212.63Unit price /UnavailableIn stock (4 units)KB ELECTRONIC

Regular price $876.80Unit price /UnavailableLow stock (3 units)LENZE

ESV402N02TXB, Lenze, 5 Horse Power, 240V, 3Ph Nema1, 174615.00, Drives

Regular price $809.00Unit price /UnavailableIn stock (9 units)Easy-Laser

Easy-Laser, D92 BTA,12-1332, Pulley Alignment System, BELT Alignment tool,

Regular price $1,587.25Unit price /UnavailableVery low stock (2 units)LEESON

Leeson, 174632.00, 2 HP, 600V, 3PH, NEMA 1,SM2, DRIVE FRÉQUENCY

Regular price $841.32Unit price /UnavailableIn stock (7 units)KB ELECTRONIC

9884, KBIC Barrier terminal board

Regular price $101.84Unit price /UnavailableIn stock (11 units)KB ELECTRONIC

8609, (KBWD-13) PWM DC Drive 1/3Hp 3A 115VAC 1PH Input 130VDC Output Chassis

Regular price $221.38Unit price /UnavailableBackorderedLENZE

EEPM2BA-SINGLE, EPM Individual Electronic Programming Module SM, SCF, SMV SERIES

Regular price $37.28Unit price /UnavailableIn stock (6 units)LEESON

174678.00, Vector Series 10Hp / 480V, 3PH(i/p) / 14.0A(o/p) Cont. / NEMA4 INDOOR

Regular price $2,624.71Unit price /UnavailableLast unit (1 unit)LENZE

Regular price $463.60Unit price /UnavailableIn stock (6 units)LENZE

Regular price $421.90Unit price /UnavailableLow stock (3 units)KB ELECTRONIC

KBVF-22D, 9572, Drive AC, 0.25HP, 240V, 1.8A, 115/230V ,1Ph In, 230V 3Ph,

Regular price $356.65Unit price /UnavailableIn stock (7 units)WEG

Regular price $172.64Unit price /UnavailableLow stock (3 units)LEESON

174636.00, Vector Series 10Hp / 600V, 3PH(i/p) / 9.0A(o/p) Cont. / NEMA1

Regular price $1,677.55Unit price /UnavailableLast unit (1 unit)LEESON

174625.00, LEESON, 5 HP, 400-480V, 3PH, NEMA 1, SM2, DRIVE FRÉQUENCY

Regular price $1,075.41Unit price /UnavailableIn stock (5 units)KB ELECTRONIC

KBSI-240D, KB ELECTRONICS. 9431C, Signal isolation board, INPUT V RANGES 0-25V 0-120VAC

Regular price $229.00Unit price /UnavailableIn stock (10 units)KB ELECTRONIC

KBCC-125R, 9937, 1.5HP MAX ,Chassis,115VAC,90VDC,REVERSING AC/DC DRIVE, Replaced by 8800, KBRG-225D,

Regular price $876.80Unit price /UnavailableIn stock (7 units)KB ELECTRONIC

9510, KBMD - Replacement Potentiometer Kit for Enclosed Controls

Regular price $48.06Unit price /UnavailableIn stock (5 units)KB ELECTRONIC

9486, KBRC, On / Off AC Line switch

Regular price $62.63Unit price /UnavailableBackorderedKB ELECTRONIC

9378, KBPC, KBPW Anti-Plug Reversing Module

Regular price $243.03Unit price /UnavailableVery low stock (2 units)

Worldwide

![KBPC-240D, KB Electronics, 9338, DC Drive,1/50 TO 2 HP,115/230V, NEMA 4X, - DC_DRIVES - KB ELECTRONIC - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/KBPC-240D.jpg?v=1756479968&width=460)

![KBPC-240D, KB Electronics, 9338, DC Drive,1/50 TO 2 HP,115/230V, NEMA 4X, - DC_DRIVES - KB ELECTRONIC - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/9339_KB_ELECTRONICS.jpg?v=1756479969&width=460)

![KBPC-240D, KB Electronics, 9338, DC Drive,1/50 TO 2 HP,115/230V, NEMA 4X, - DC_DRIVES - KB ELECTRONIC - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_KB.png?v=1756479968&width=460)

![KBMD-240D, KB Electronics DC Drives, KBMD Series, 9370 SCR, 1/100-2HP CONTROL, 115/230VAC, 1-WAY - DRIVE AC/DC - KB ELECTRONIC - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/kbmd_2.jpg?v=1756480809&width=460)

![KBMD-240D, KB Electronics DC Drives, KBMD Series, 9370 SCR, 1/100-2HP CONTROL, 115/230VAC, 1-WAY - DRIVE AC/DC - KB ELECTRONIC - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/9860._KB.jpg?v=1756480809&width=460)

![KBMD-240D, KB Electronics DC Drives, KBMD Series, 9370 SCR, 1/100-2HP CONTROL, 115/230VAC, 1-WAY - DRIVE AC/DC - KB ELECTRONIC - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/KBSI-240D_KB_ISOLATOR_SIGNAL.jpg?v=1756480809&width=460)

![ESV222N02YXB, VFD, SMV, Drive 3 Hp, 240 Volts, 1/3Ph, Nema1, 9.6Amps, - AC DRIVES - E-Motor Nations - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur - fan](http://www.emotornations.com/cdn/shop/files/Screenshot2024-05-29185629.png?v=1756414179&width=460)

![125DVC-Z2016, DART, 125DV, 1HP, 90-180V, DC Speed Control, Dart Control - DRIVE AC/DC - DART CONTROL - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/125DVC-Z2016.jpg?v=1756480271&width=460)

![125DVC-Z2016, DART, 125DV, 1HP, 90-180V, DC Speed Control, Dart Control - DRIVE AC/DC - DART CONTROL - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_KB_7d6c7038-ef61-492c-ae2c-c38be822ab0d.png?v=1756480271&width=460)

![L510-201-H1-U, Westinghouse, Drives, VFD, 1 Hp, 230V IN, 230V output, Ip20 - FRÉQUENCY VARIABLE VECTOR DRIVE - WESTINGHOUSE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/L510-101-H1-U_WESTINGHOUSE_4b256cb0-8d79-4f0a-bcca-18a4fe3db568.jpg?v=1756479638&width=460)

![L510-201-H1-U, Westinghouse, Drives, VFD, 1 Hp, 230V IN, 230V output, Ip20 - FRÉQUENCY VARIABLE VECTOR DRIVE - WESTINGHOUSE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_WESTINGHOUSE_d022bd4b-8ee3-4c93-b746-7ca97cf3cdca.jpg?v=1756479638&width=460)

![KBMG-212D, KB, Drive, DC, 120/240VAC, 1.2A, Chassis Thru 1/6HP, SCR, 90/180VDC Armature, Regen - DC_DRIVES - KB ELECTRONIC - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur - fan](http://www.emotornations.com/cdn/shop/products/image_84792790-4dd8-4fa6-97e7-c609eb39cf1d.jpg?v=1756414659&width=460)

![PESWS-25V24AX-RM33, Weg, 5HP, 1PH, 25 Amps, 230V, Nema 4X, MotorStarter - ACCESSORIES MOTORS & PARTS - WEG - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/PESW-9V24AX-R28_WEG_b000aadc-9ebd-41c0-bb18-a716580c7513.jpg?v=1756479469&width=460)

![PESWS-25V24AX-RM33, Weg, 5HP, 1PH, 25 Amps, 230V, Nema 4X, MotorStarter - ACCESSORIES MOTORS & PARTS - WEG - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_WEG_1871e30d-4b43-4f02-b3fb-54d7e0918ce7.png?v=1756479470&width=460)

![Leeson, 174632.00, 2 HP, 600V, 3PH, NEMA 1,SM2, DRIVE FRÉQUENCY - FRÉQUENCY VARIABLE VECTOR DRIVE - LEESON - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/174603.00_42094a65-9d6d-42ab-b8a6-473cce705834.jpg?v=1756480737&width=460)

![ESV751N02YXB, SMV SERIES SENSORLESS Vector 1Hp / 240V, 1/3PH(i/p) / 230V, 3PH(o/p) / 4.2A(o/p) Cont. / NEMA1 - AC DRIVES - E-Motor Nations - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur - fan](http://www.emotornations.com/cdn/shop/files/ESV751N02YXB.jpg?v=1756412494&width=460)

![ESV751N02YXB, SMV SERIES SENSORLESS Vector 1Hp / 240V, 1/3PH(i/p) / 230V, 3PH(o/p) / 4.2A(o/p) Cont. / NEMA1 - AC DRIVES - E-Motor Nations - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur - fan](http://www.emotornations.com/cdn/shop/files/t3.png?v=1756412494&width=460)

![ESV371N01SXB, SMV SERIES SENSORLESS Vector 0.5Hp / 120/240V, 1PH(i/p) / 230V, 3PH(o/p) / 2.4A(o/p) Cont. / NEMA1 - AC DRIVES - E-Motor Nations - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur - fan](http://www.emotornations.com/cdn/shop/files/ESV371N01SXB_1eae01f3-ee6c-4420-a044-b345fc2a4909.jpg?v=1756412508&width=460)

![174607.00, VectorSeries 0.50Hp / 240V, 1/3PH(i/p) / 230V, 3PH(o/p) / 2.4A(o/p) Cont. / NEMA1 - AC DRIVES - E-Motor Nations - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur - fan](http://www.emotornations.com/cdn/shop/files/ESV371N01SXB-t.png?v=1756412508&width=460)

![174625.00, LEESON, 5 HP, 400-480V, 3PH, NEMA 1, SM2, DRIVE FRÉQUENCY - FRÉQUENCY VARIABLE VECTOR DRIVE - LEESON - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/174603.00_eba65b52-acc0-4efd-9fbf-d45083106d81.jpg?v=1756481024&width=460)

![174625.00, LEESON, 5 HP, 400-480V, 3PH, NEMA 1, SM2, DRIVE FRÉQUENCY - FRÉQUENCY VARIABLE VECTOR DRIVE - LEESON - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_LEESON_eb6e5706-ae82-4051-bd8a-82ecad5c6d67.png?v=1756481024&width=460)

![KBCC-125R, 9937, 1.5HP MAX ,Chassis,115VAC,90VDC,REVERSING AC/DC DRIVE - DRIVE AC/DC - KB ELECTRONIC - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/KBCC-125R.jpg?v=1756480267&width=460)