Mobil

Grease, Polyrex EM, Electric Motor Bearing Grease, Blue color

Prix habituel $67.85Prix unitaire /IndisponibleEn stock (3058 unités)MOBIL_1

Grease, Polyrex EM, Electric Motor Bearing Grease, EM, Blue color

Prix habituel $67.85Prix unitaire /IndisponibleEn stock (1736 unités)A.O SMITH

No 30, A.O SMITH, 1/25 Hp, 115V, JA2N191N, 1550 Rpm, 1.6A, AO132, 60Hz

Prix habituel $129.95Prix unitaire /IndisponibleEn stock (22 unités)OMNIDRIVE

11811, eMotortek, Repl. 7190-1235, 7190-1508 , FASCO, ER40200, VENMAR, 1/6HP, 120 VOLTS

Prix habituel $464.37Prix unitaire /IndisponibleEn stock (12 unités)Dolph's

ER-41 – Varnish Polyurethane Rouge - 1 SPRAY CAN 20 Oz

Prix habituel $38.08Prix unitaire /IndisponibleEn stock (145 unités)Sprayon

EL601, Sprayon,Red Insulating Varnish 432g,Dielectric, 15.25 oz, EL601

Prix habituel $44.95Prix unitaire /IndisponibleEn stock (18 unités)Mobil

Grease, Polyrex EM, Electric Motor Bearing Grease, Blue color

Prix habituel $67.85Prix unitaire /IndisponibleEn stock (10 unités)OMNIDRIVE

R-P1000-B4, Canarm, 1/20 Hp, 1600 RPM, 120V, 8213917501,2 Speeds, 1.7A

Prix habituel $299.00Prix unitaire /IndisponibleEn stock (16 unités)OMNIDRIVE

SS358, 1/15 HP, 1550 RPM, 115V, 2.2 AMPS, CW, ODP, 2.2 AMPS eMotorteK

Prix habituel $107.21Prix unitaire /IndisponibleBientôt de retourROTOM

R2-R462, 7190-2271, 1/17 HP, 1660/3 SPD, 115V, 1.2 AMPS, VENMAR, ROTOM,

Prix habituel De $368.38Prix unitaire /IndisponibleEn stock (17 unités)MOBIL_1

Insulating oils, Mobil, Voltesso 35, Di-électric. oil, Transformer, Motor Pump, 121512

Prix habituel De $31.73Prix unitaire /IndisponibleEn stock (51 unités)LEESON

Leeson 900163.11, Carbon Brush, 0.812" L x 0.787" W x 0.38" T, K174 Grade, Graphite

Prix habituel $51.20Prix unitaire /IndisponibleEn stock (22 unités)OMNIDRIVE

SS462, eMotorteK, 7190-2271, 1/12 HP, 1625/3 SPD, 115V, 1.2 AMPS, VENMAR, R2-R462, VENMAR REPLACE

Prix habituel $278.00Prix unitaire /IndisponibleEn stock (7 unités)OMNIDRIVE

SS030, eMotorteK Motor, 1/25 HP, 1550 RPM, 115V, Replace Trane 70270010, ODP

Prix habituel $129.95Prix unitaire /IndisponibleEn stock (35 unités)BALDOR

CDP3445, Baldor, 1 HP, 1750 RPM, 90VDC, TEFC, 34-5990-3675, Severe duty, DC Motors

Prix habituel $1,159.00Prix unitaire /IndisponibleStock faible (3 unités)VENMAR

13038 ,Venmar. Solo 1.5,2.0, 1.8 HE, 2.6 HE Circuit Board, 2000&3000HE

Prix habituel $475.00Prix unitaire /IndisponibleMARATHON

B319, Marathon, 3/4 HP,1800 RPM, 056C17D2074, 115/230V, FR 56, C426V1

Prix habituel $365.45Prix unitaire /IndisponibleEn stock (7 unités)BALDOR

36FN3000C01SP, Baldor, EXTERNAL FAN, OD 5.25'', Diameter, 0.912 ID

Prix habituel $71.41Prix unitaire /IndisponibleEn stock (11 unités)OMNIDRIVE

SS217, 1/40 HP, 208-240V, 1550 RPM, 7173-0646, eMotorteK, 2868407152, O6-R217

Prix habituel $111.00Prix unitaire /IndisponibleStock très faible (2 unités)CENTURY

9608, Ao Smith, 1/20Hp, 1100 Rpm, 115V, ODP, HVAC, 5KCP29BK6747S, 7176-3026

Prix habituel $411.96Prix unitaire /IndisponibleStock très faible (2 unités)OMNIDRIVE

Prix habituel $279.00Prix unitaire /IndisponibleEn stock (9 unités)Dolph's

ER-44 – Varnish Polyurethane Rouge – SPRAY CAN 16 Oz

Prix habituel $32.35Prix unitaire /IndisponibleEn stock (18 unités)PACKARD

START CAPACITOR SC350-330G, 340-385 UF, 350 VAC,

Prix habituel $69.95Prix unitaire /IndisponibleEn stock (11 unités)ELCO MOTORS

EC9W230, Elco, 9W, 230V, 1550 RPM, NU9-20-4, NUT6B09PUN201, Unit Bearing

Prix habituel $107.84Prix unitaire /IndisponibleEn stock (11 unités)OMNIDRIVE

eMotorteK, 7124-2308, C08E10A, CK48HC21K88, 1/4 HP, 1650/2spd,115V, Loren cook,

Prix habituel $419.00Prix unitaire /IndisponibleEn stock (16 unités)CENTURY

GF2034, Ao Smith, 1/3 Hp, 1725 Rpm, 115V, Frame: 48, 316P759, Century

Prix habituel $264.41Prix unitaire /IndisponibleEn stock (4 unités)LOREN COOK

C11E4A, LOREN COOK, 3/4 HP,115 VOLTS, 7126-4392, 7124-2307, FASCO,HVAC

Prix habituel $672.36Prix unitaire /IndisponibleStock très faible (2 unités)ELCO MOTORS

EC-9W115, ELCO NET3T09PUN302, 9W, 115 VOLTS , 1550 RPM, 0.58A, HUBLESS

Prix habituel $123.57Prix unitaire /IndisponibleEn stock (5 unités)OMNIDRIVE

63745-0, JE2E024N, 1/30, 1550 RPM, 2SPD, 115V, PENN BARRY, eMotorteK

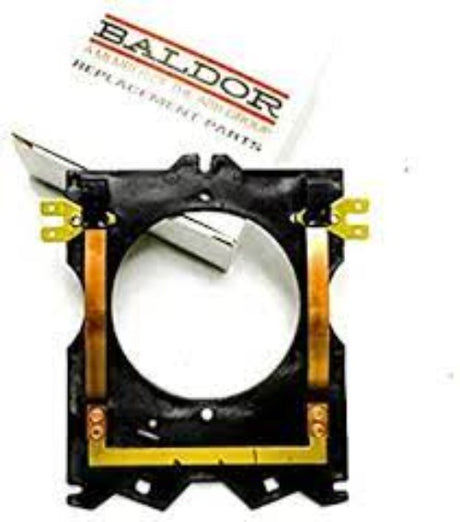

Prix habituel $368.57Prix unitaire /IndisponibleEn stock (13 unités)BALDOR

SP5064SP, Baldor, stationary switch 182/184T, 213/215T, Fit on L1410T& L1510T

Prix habituel $118.99Prix unitaire /IndisponibleEn stock (9 unités)ROTOM

ROTOM, R3-R358, 1/20,1550 RPM,120 VOLTS,Refrigeration,SS358 eMotorteK,

Prix habituel $104.95Prix unitaire /IndisponibleEn stock (44 unités)LEESON

RC35-240, Capacitor Oval Run, 35uF 240vac, orc35240, 2.17''x1.31''x3.94''

Prix habituel $53.95Prix unitaire /IndisponibleEn stock (30 unités)STEARNS

473008315U01, STEARNS, SINPAC, IR 40A, 115V, Instant reverse Motor, 002789.02, Leeson, 40A

Prix habituel $399.85Prix unitaire /IndisponibleEn stock (11 unités)BALDOR

CDP3440, Baldor, 3/4HP, 1750 Rpm, 90VDC, 34-5990-3662,098002.00,C42D17FK2D

Prix habituel De $99.73Prix unitaire /IndisponibleEn stock (21 unités)ELCO MOTORS

EC18W115, Elco, 18W, 115V, NUT6B18PUN301, 1550 Rpm, NU18-30-2

Prix habituel $163.99Prix unitaire /IndisponibleEn stock (7 unités)Seymour

620-1525, Seymour, Tool CRIB, Red Insulating Varnish, 155C, Air dry,

Prix habituel $26.52Prix unitaire /IndisponibleBientôt de retour

Worldwide

![Grease, Mobil 1, Polyrex EM, Electric Motor Bearing Grease, EM, Blue color - ACCESSORIES MOTORS & PARTS - MOBIL_1 - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/91BVyBVfMzL._SX569_cdb0795c-6262-402a-90dd-a0469e4d27f1.jpg?v=1756414414&width=460)

![Grease, Mobil 1, Polyrex EM, Electric Motor Bearing Grease, EM, Blue color - ACCESSORIES MOTORS & PARTS - MOBIL_1 - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/91BVyBVfMzL._SX569.jpg?v=1756479623&width=460)

![Grease, Mobil 1, Polyrex EM, Electric Motor Bearing Grease, EM, Blue color - ACCESSORIES MOTORS & PARTS - MOBIL_1 - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_MOBIL_1.png?v=1756479623&width=460)

![No 30, A.O SMITH, 1/25 Hp, 115V, JA2N191N, 1550 Rpm, 1.6A, AO132, 60Hz - HVAC ELECTRIC MOTOR - A.O SMITH - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur - fan](http://www.emotornations.com/cdn/shop/products/718b0236-c0f2-4be0-82f7-471775fcc904.jpg?v=1756414650&width=460)

![11811, Omnidrive, Repl. 7190-1235, 7190-1508 , FASCO, ER40200, VENMAR, 1/6HP, 120 VOLTS - HVAC ELECTRIC MOTOR - OMNIDRIVE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/11811.jpg?v=1756480982&width=460)

![Grease, Mobil 1, Polyrex EM, Electric Motor Bearing Grease, EM, Blue color - ACCESSORIES MOTORS & PARTS - MOBIL_1 - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/91BVyBVfMzL._SX569_eac5baaf-b5e3-418e-8b09-3f2af2c51d68.jpg?v=1756414166&width=460)

![SS358, 1/15 HP, 1550 RPM, 115V, 2.2 AMPS, CW, ODP, 2.2 AMPS OMNIDRIVE - HVAC ELECTRIC MOTOR - OMNIDRIVE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/SS358.jpg?v=1756480713&width=460)

![R2-R462, 7190-2271, 1/17 HP, 1660/3 SPD, 115V, 1.2 AMPS, VENMAR, ROTOM, - HVAC ELECTRIC MOTOR - ROTOM - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/R2-R462_3c0a3e4b-713d-49ed-948b-7bb1281d9c22.jpg?v=1756480914&width=460)

![R2-R462, 7190-2271, 1/17 HP, 1660/3 SPD, 115V, 1.2 AMPS, VENMAR, ROTOM, - HVAC ELECTRIC MOTOR - ROTOM - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/TRC7.5_PACKARD.jpg?v=1756480914&width=460)

![R2-R462, 7190-2271, 1/17 HP, 1660/3 SPD, 115V, 1.2 AMPS, VENMAR, ROTOM, - HVAC ELECTRIC MOTOR - ROTOM - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_ROTOM_59ccdb8c-d39e-4907-9f76-8f163d80ad61.png?v=1756480914&width=460)

![Insulating oils, Mobil, Voltesso 35, Di-électric. oil, Transformer, Motor Pump, 121512 - ACCESSORIES MOTORS & PARTS - MOBIL_1 - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/MOBIL_Voltsesso_35_205L.jpg?v=1756479389&width=460)

![Insulating oils, Mobil, Voltesso 35, Di-électric. oil, Transformer, Motor Pump, 121512 - ACCESSORIES MOTORS & PARTS - MOBIL_1 - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/MOBIL_Voltsesso_35_18.9L.jpg?v=1756479390&width=460)

![Insulating oils, Mobil, Voltesso 35, Di-électric. oil, Transformer, Motor Pump, 121512 - ACCESSORIES MOTORS & PARTS - MOBIL_1 - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/MOBIL1_VOLTESSO_1L.jpg?v=1756479390&width=460)

![Insulating oils, Mobil, Voltesso 35, Di-électric. oil, Transformer, Motor Pump, 121512 - ACCESSORIES MOTORS & PARTS - MOBIL_1 - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_MOBIL_1_d2cc65f9-93f3-436d-b357-30a521225ca7.png?v=1756479390&width=460)

![Leeson 900163.11, Carbon Brush, 0.812" L x 0.787" W x 0.38" T, K174 Grade, Graphite - ACCESSORIES MOTORS & PARTS - LEESON - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LEESON_900163.11.jpg?v=1756479564&width=460)

![Leeson 900163.11, Carbon Brush, 0.812" L x 0.787" W x 0.38" T, K174 Grade, Graphite - ACCESSORIES MOTORS & PARTS - LEESON - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_LEESON_030d7947-825d-4b40-a9f5-23f9cd7a3bde.png?v=1756479564&width=460)

![SS462, OMNIDRIVE, 7190-2271, 1/12 HP, 1625/3 SPD, 115V, 1.2 AMPS, VENMAR, R2-R462, VENMAR REPLACE - HVAC ELECTRIC MOTOR - OMNIDRIVE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/SS462-B.jpg?v=1756480852&width=460)

![SS462, OMNIDRIVE, 7190-2271, 1/12 HP, 1625/3 SPD, 115V, 1.2 AMPS, VENMAR, R2-R462, VENMAR REPLACE - HVAC ELECTRIC MOTOR - OMNIDRIVE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_OMNIDRIVE_63885595-860b-474e-9f1b-303b68a76f63.jpg?v=1756480852&width=460)

![SS030, OMNIDRIVE, 1/25 HP, 1550 RPM, 115V, Replace Trane 70270010, ODP - HVAC ELECTRIC MOTOR - OMNIDRIVE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/SS030.jpg?v=1756480875&width=460)

![SS030, Omnidrive Motor, 1/25 HP, 1550 RPM, 115V, Replace Trane 70270010, ODP - HVAC ELECTRIC MOTOR - OMNIDRIVE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur - fan](http://www.emotornations.com/cdn/shop/files/Capture_d_ecran_2024-10-06_170634.png?v=1756480875&width=460)

![CDP3445, Baldor, 1 HP, 1750 RPM, 90VDC, TEFC, 34-5990-3675, Severe duty, DC Motors - DC MOTORS - BALDOR - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/CDP3445_BALDOR.jpg?v=1756479908&width=460)

![B319, Marathon, 3/4 HP,1800 RPM, 056C17D2074, 115/230V, FR 56, C426V1 - HVAC ELECTRIC MOTOR - MARATHON - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/B319_MARATHON.jpg?v=1756480681&width=460)

![B319, Marathon, 3/4 HP,1800 RPM, 056C17D2074, 115/230V, FR 56, C426V1 - HVAC ELECTRIC MOTOR - MARATHON - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_MARATHON_13a76b09-ac32-42ce-ba9e-c2cbda98d3e4.png?v=1756480681&width=460)

![36FN3000C01SP, Baldor, EXTERNAL FAN, OD 5.25'', Diameter, 0.912 ID - ACCESSORIES MOTORS & PARTS - BALDOR - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur - fan](http://www.emotornations.com/cdn/shop/products/36FN3000C01SP.jpg?v=1756479809&width=460)

![SS217, 1/40 HP, 208-240V, 1550 RPM, 7173-0646, OMNIDRIVE, 2868407152, O6-R217 - HVAC ELECTRIC MOTOR - OMNIDRIVE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/ss217.jpg?v=1756480940&width=460)

![9608, Ao Smith, 1/20 HP, 1100 Rpm, 115V, ODP, HVAC, 5KCP29BK6747S, 7176-3026 - HVAC ELECTRIC MOTOR - CENTURY - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/9608_CENTURY.jpg?v=1756479909&width=460)

![SS250, 1/70 HP, 1550 RPM, 115V, 0.65A, CWSE, OMNIDRIVE, 2868-509-042LM, 72730867, 2868509042, 605850M0, 605850M0, 71730867, 2868509036, R250 - HVAC ELECTRIC MOTOR - OMNIDRIVE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/ss250.jpg?v=1756480939&width=460)

![EC9W230, Elco, 9W, 230V, 1550 RPM, NU9-20-4, NUT6B09PUN201, Unit Bearing - UNIT BEARING MOTORS - ELCO MOTORS - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/EC9W230_ELCO.jpg?v=1756479475&width=460)

![EC9W230, Elco, 9W, 230V, 1550 RPM, NU9-20-4, NUT6B09PUN201, Unit Bearing - UNIT BEARING MOTORS - ELCO MOTORS - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/LOGO_ELCO_0c91fac9-e422-4c1d-9d8c-fbb549296a0f.png?v=1756479475&width=460)

![OMNIDRIVE, 7124-2308, C08E10A, CK48HC21K88, 1/4 HP, 1550/2SPD,115V, LOREN COOK, - HVAC ELECTRIC MOTOR - OMNIDRIVE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/C08E10A_LOREN_COOK.jpg?v=1756480791&width=460)

![C11E4A, LOREN COOK, 3/4 HP,115 VOLTS, 7126-4392, 7124-2307, FASCO,HVAC - DIRECT DRIVE MOTOR - LOREN_COOK - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/C11E4A_LOREN_COOK.jpg?v=1756479997&width=460)

![EC-9W115, ELCO NET3T09PUN302, 9W, 115 VOLTS , 1550 RPM, 0.58A, HUBLESS - RÉFRIGÉRATION MOTORS - ELCO MOTORS - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/EC-9W115_fcb76294-e9ff-4450-8002-0bc8b2d05326.jpg?v=1756480408&width=460)

![63745-0, JE2E024N, 1/30, 1550 RPM, 2SPD, 115V, PENN BARRY, OMNIDRIVE - HVAC ELECTRIC MOTOR - OMNIDRIVE - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/63745_061a11a8-7ca7-4a87-8381-3683abba494c.jpg?v=1756480736&width=460)

![ROTOM, R3-R358, 1/20,1550 RPM,120 VOLTS,Refrigeration,SS358 OMNIDRIVE, - HVAC ELECTRIC MOTOR - ROTOM - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/R3-R358_91fe45fb-1b85-4fa5-a67d-0941742ae1a4.jpg?v=1756480755&width=460)

![ROTOM, R3-R358, 1/20,1550 RPM,120 VOLTS,Refrigeration,SS358 OMNIDRIVE, - HVAC ELECTRIC MOTOR - ROTOM - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur - fan](http://www.emotornations.com/cdn/shop/files/Capture_d_ecran_2024-10-06_163022.png?v=1756480756&width=460)

![473008315U01, STEARNS, SINPAC, IR 40A, 115V, Instant reverse Motor, 002789.02, Leeson, 40A - ACCESSORIES MOTORS & PARTS - STEARNS REXNORD - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/Logo_Stearns_Rexnord.png?v=1756479699&width=460)

![CDP3340, Baldor, 3/4HP, 1750 Rpm, 90VDC, 34-5990-3662,098002.00,C42D17FK2D - DC MOTORS - BALDOR - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/CDP3340_Baldor.jpg?v=1756479904&width=460)

![CDP3340, Baldor, 3/4HP, 1750 Rpm, 90VDC, 34-5990-3662,098002.00,C42D17FK2D - DC MOTORS - BALDOR - electric motors - [product_tags]- motor electric - moteur électrique - moteurs - drive - replacement - venmar - hvac - méchoui - capacitor - condensateur](http://www.emotornations.com/cdn/shop/products/BP5000BK08SP_e1bba5ca-758a-4819-be46-32a0255b8979.jpg?v=1756479904&width=460)