Allcomposite | SKU :

EMN-017044

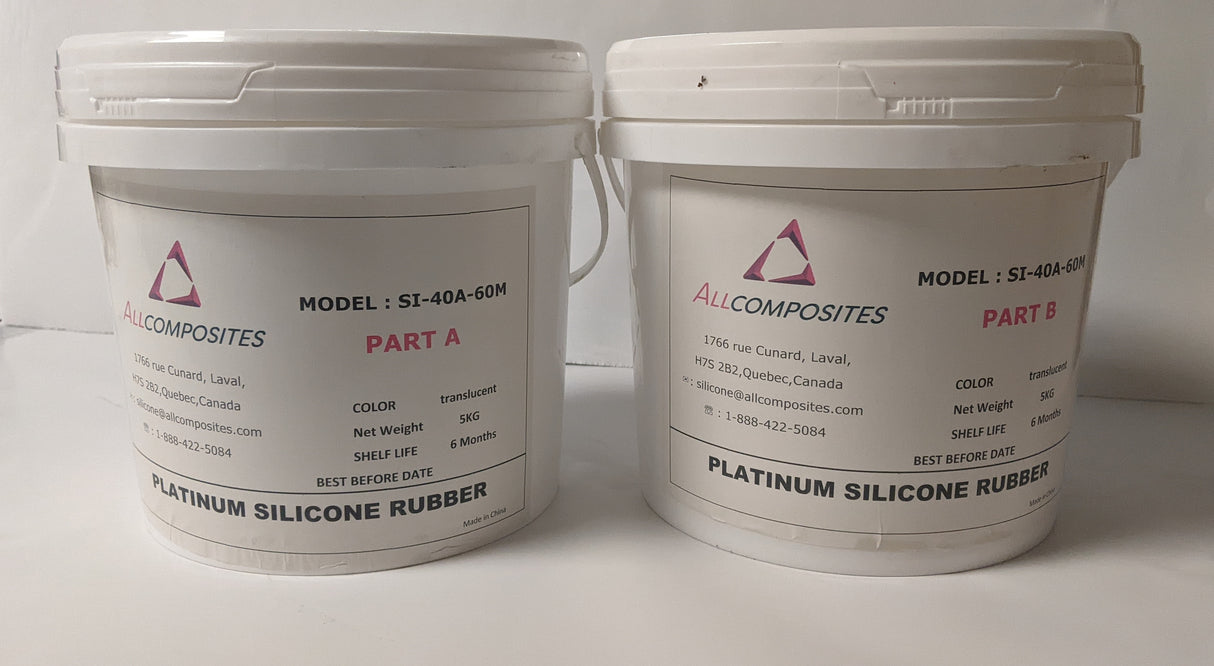

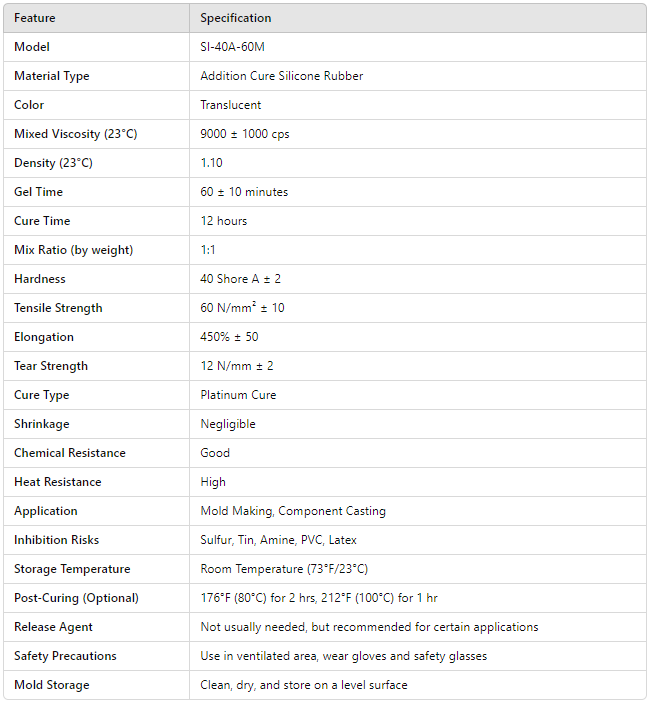

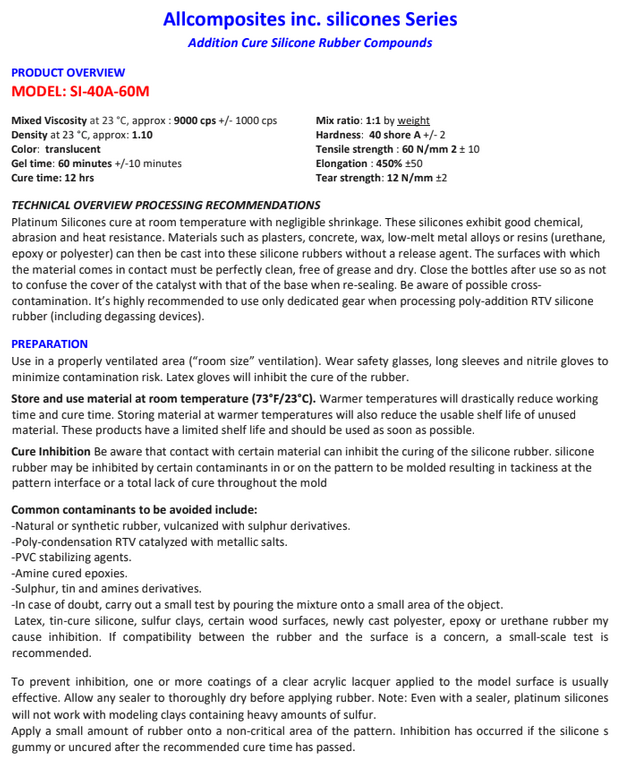

SI-40A-60M, Platinum Silicone Rubber Compounds, 2x5Kg Addition Cure

Prix habituel

$289.85

Prix unitaire

/

Indisponible

SI-40A-60M, Platinum Silicone Rubber Compounds, 2x5Kg Addition Cure est en rupture de stock et sera expédié dès qu’il sera de retour en stock.

Impossible de charger la disponibilité pour le Service de retrait

shipping

Estimation des frais de livraison

Veuillez corriger les erreurs suivantes :

Description

Description

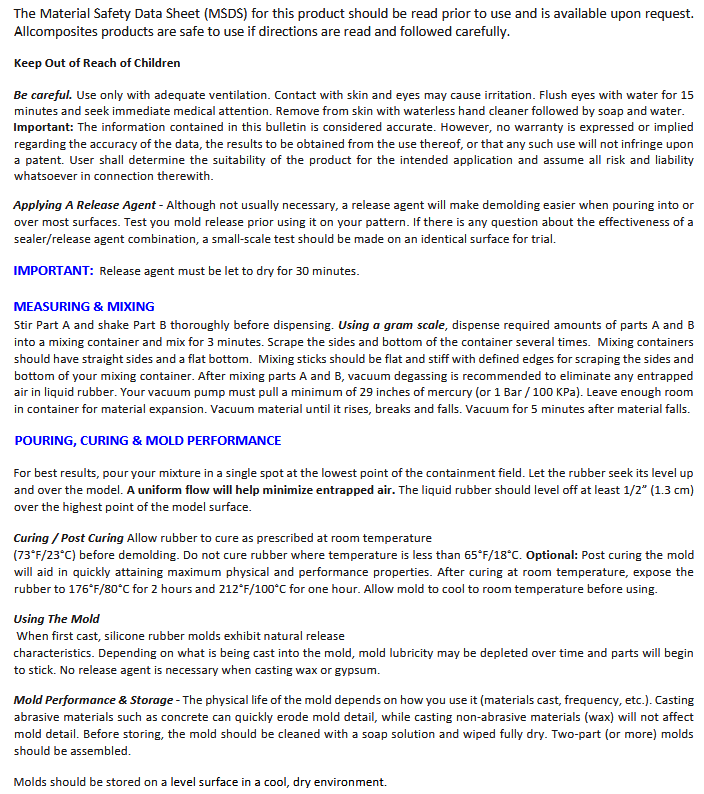

SI-40A-60M, Platinum Silicone Rubber Compounds, 2x5Kg Addition Cure

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.